OPC UA, Time Sensitive Networking (TSN) and Single Pair Ethernet (SPE) are just three of many examples of network technologies that have been developed and introduced in recent years with a view to the fourth industrial revolution. In this context, OPC UA is a standard for data exchange as a platform-independent, service-oriented architecture, TSN defines standards of mechanisms for transmitting data over Ethernet networks, and SPE enables the use of Ethernet throughout industrial automation in a cost-effective manner for the first time. Current research in this area indicates that these technologies are currently still little used and, above all, only rarely in combination.

"We would like to change that with the development of a reference system. Technologies such as TSN, OPC UA, SPE and others should be able to be tested, evaluated and demonstrated individually and in combination," says Dr. Lukasz Wisniewski from the Institute Industrial IT (inIT) at the Ostwestfalen-Lippe University of Applied Sciences and Arts. To achieve this goal, the project "CINI4.0: Convergent Network Architecture for Industry 4.0" was launched in August 2021. Wisniewski represents the project in Germany together with his colleague Dr. Sebastian Schriegel from Fraunhofer IOSB-INA. In addition to the two German research institutions, research groups from KU Leuven and Ghent Univiersity Belgium are also involved in the international CORNET project. There is also a high level of participation from industry. A total of 22 companies, including the two CIIT partners TOSIBOX and Hilscher, are supporting and managing the project, which is funded by the German Federal Ministry for Economic Affairs and Energy with 400,000€.

The potential applicability of the technologies is to be investigated on the basis of technical demonstration plants at the SmartFactoryOWL in Lemgo. "This enables us to analyze the performance and limits of the technologies in different configurations and under different conditions," explains Dr. Wisniewski, project manager of the german subproject.

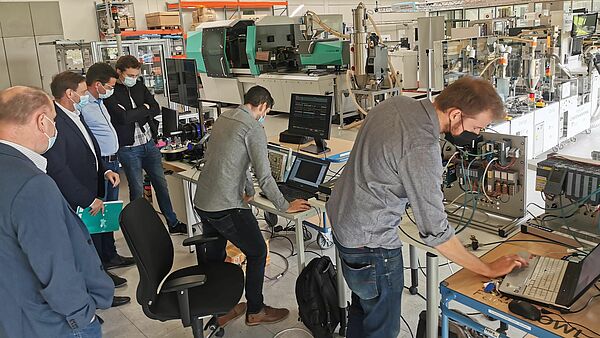

After the first project meeting had to be held virtually in September, parts of the partners came together live in October. A delegation of the Belgian partners made their way to Lemgo and tested the first concepts in the SmartFactoryOWL over two days together with representatives from inIT and Fraunhofer IOSB-INA.

In addition to the content-related work, several workshops and training courses for industrial companies are to be offered over the course of the two project years. There, the properties of the technologies under investigation will be presented.