A consortium spanning the whole of Ostwestfalen-Lippe is currently putting machine learning methods through their paces for use in industrial production facilities. The goal of the project is to compile an interactive toolbox with AI and learning algorithms suitable for industrial use, thus also enabling small and medium-sized manufacturing companies to use AI. In this context, the Institute for Industrial Information Technology (inIT) is conducting research on the transferability of machine learning as part of the technology network it's OWL together with the Institute for Energy Research (iFE) of TH OWL, the Fraunhofer Institutes IOSB-INA and IEM, Bielefeld University and Bielefeld University of Applied Sciences. Industrial partners such as Lenze SE, Weidmüller and HANNING ELEKTRO-WERKE provide concrete use cases from their production plants. These range from quality inspection in engine manufacturing, to process optimization in stamping plants, to component monitoring in electroplating plants.

What's the challenge?

Machine learning algorithms cannot simply be applied one-to-one to industrial production processes. AI algorithms learn on so-called training data. However, while training data, such as pictures of dogs, cats or street signs, are plentiful in everyday applications, they can often only be generated by machines to a limited extent. After all, no one drives their equipment to critical states just to generate data. In addition, data in machine systems is often not very meaningful or difficult to interpret. In production plants, adverse conditions prevail, even for measurement processes. For example, vibrations, temperature fluctuations or corrosive liquids affect the sensor technology in such a way that it delivers distorted, delayed or, in some cases, no data at all. These are circumstances that classical machine learning algorithms struggle with.

What is inIT doing?

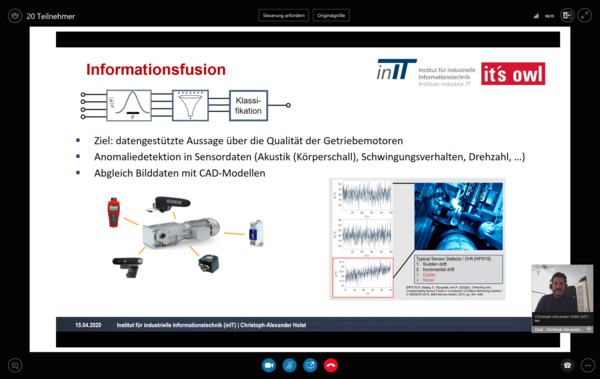

To counteract these uncertainties in machine data, methods are being developed at inIT that combine the strengths of machine learning and information fusion. On the one hand, complex concepts are learned using training data, and on the other hand, fusion ensures that sensor dropouts and distorted data have no effect on the actual application. This is done by exploiting the fact that machine data acquired by multisensors is almost always partially redundant, meaning that it often provides the same information in a different guise. Such partial redundancies normally negatively affect learning algorithms. Through information fusion, however, inIT exploits precisely this property to make AI applications for industry more robust and performant.