Assistant systems for supporting manufacturing, mounting and quality assurance are relatively rare at SMEs. For supporting employees in production with latest technologies, “mobile solutions are demanded that can be applied everywhere in the companies and are not bounded to stationary working places”, explains Professor Carsten Röcker, project leader and board member of inIT. At this point “MARI” comes into play: Together with partners from industry and science, the researchers from Lemgo develop and evaluate the prototype of the modular and intelligent Augmented Reality (AR)-based assistant systems for mobile application scenarios at SMEs.

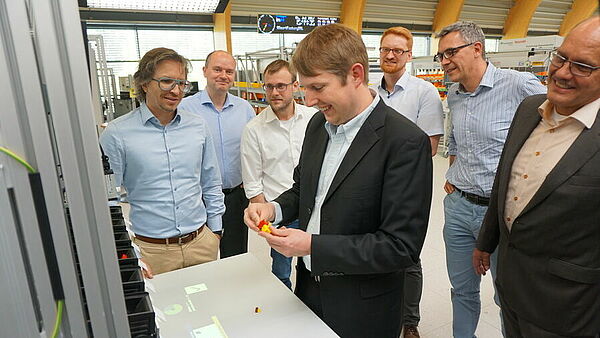

Augmented Reality provides an opportunity for employees to “keep pace with technological developments and increasing demands of the digital factory”. The real world will be overlapped with digital objects – with the help of projections or AR glasses. After the researchers from Lemgo have dealt intensively with assistant systems at stationary manual workplaces, now mobile interaction technologies shall be realized.

Röcker explains the goal of the research project as follows: “The planned project will be mobile and suitable for various application scenarios. Because new activities will be learned within one repetition and a wide range of industrial activities will be covered, employees can also be supported with Artificial Intelligence.” The modular composition enables an easy and fast adaption of the system to various activities in production, mounting or quality assurance. Because of the integrated sensor technology working activities can be multimodally identified, analyzed and models for the future assistance of manual activities build up.

Because of the modular architecture, different components for interaction can be combined – depending on the respective approach. “Via a generic interface various interaction devices can be connected, like Wearables, AR data glasses or eye tracker that can be combined with each other”, explains Röcker the procedure. Employees can use the suitable interaction devices for each specific application: For example can be changed from a tablet to AR glasses, when the personnel needs both hands free.

Röcker summarizes: “Our vision is knowledge transfer and a facilitation of work stages – like e.g. error analysis or plant maintenance.” The human always takes the center stage: Supporting and error reduction while mounting as well as short learning times are just a few benefits of computer based assistance systems to support the human in the digital factory of the future. For the researchers from Lemgo intelligent assistance systems are the key for making manageable the increasing complexity of plants. For years they are doing research on the topic area of Human-Machine-Interaction for Industry 4.0.

About MARI:

The project name MARI means: “Augmented Reality Assistance Systems for Mobile Application Scenarios in Industry”. Collaboration partners are besides the Institute Industrial IT (inIT) of OWL University Bosch Rexroth AG and Wassermann Technologie GmbH. The Fraunhofer Application Center IOSB-INA scientifically supports the project. The BMBF funds the project with 450,000 € for four years. Since 2009 the inIT is doing research under the roof of the research and development center CENTRUM Industrial IT (CIIT) together with partners from industry and science.