After a three-year period, the project "Montexas 4.0: Excellent Assembly in the Context of Industry 4.0", funded by the German Federal Ministry of Education and Research, was successfully completed this year. The object of the joint project was to research and test new forms of assistance-supported assembly work and associated changes in work organization and personnel development.

"An increased number of variants makes assembly work more complex. This leads to increased information processing in assembly and cognitive ergonomics, i.e. human-technology interaction, is becoming increasingly important. Together with local companies, we have developed, researched and implemented innovative assembly assistance system solutions," says Philip Sehr, research associate at the Institute for Industrial Information Technology (inIT), describing the background.

In addition to the iniT, the Lab for Industrial Engineering at the Ostwestfalen-Lippe University of Applied Sciences (TH OWL), the Institute of Psychology at the University of Greifswald, and the two companies Spier Fahrzeugwerk and Homag Kantentechnik were also among the Montexas 4.0 project partners.

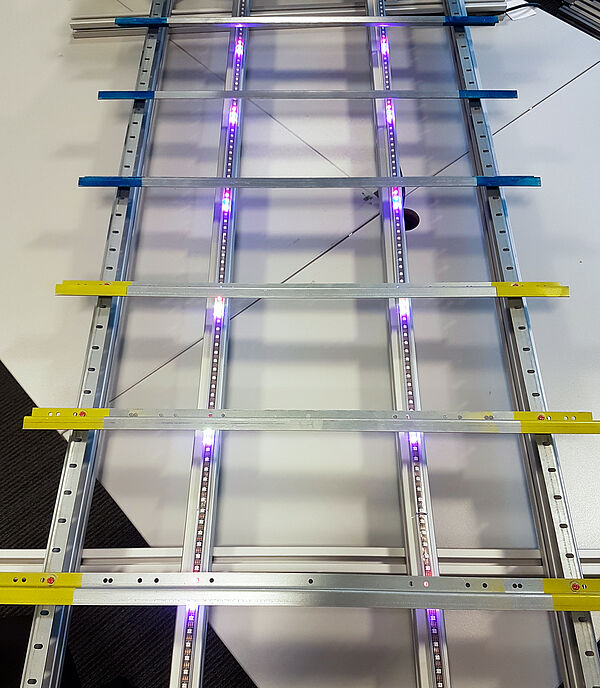

The inIT was significantly involved in two use cases during the course of the project. In the first case, the knowledge gained was tested in an industrial environment using prototype assistance systems. For this purpose, the optical and structural optimizations of the assembly information, for example through simplified construction drawings that allow the representation according to user requirements, were automated. In addition, advanced display options such as put-to-light systems were used. "In addition, we succeeded in developing a novel system that combines simple information presentation with low investment costs. As a result, we were able to increase productivity by more than 13%," Sehr and Natalia Moriz, board members at inIT and also involved in the project, say in unison.